Making Ductwork Accessible

In the kitchen exhaust cleaning industry, a common challenge is inaccessible ductwork. While a hood might sparkle after a service, the integrity of the fire suppression system depends entirely on the sections of the ductwork that are hidden behind walls or above ceilings. According to NFPA 96 standards, cleaning to 50 microns (effectively bare metal) is a requirement, yet this is physically impossible if the system includes long stretches of ductwork without openings. Without these openings, grease and other combustable material may accumulate in inaccessible areas, creating a fuel load that can turn a small stovetop flare-up into a catastrophic building fire.

Proper positioning of openings in the ductwork is governed by NFPA 96, which mandates that access must be provided at every change of direction and at specific intervals along horizontal and vertical runs. For systems where personnel cannot physically enter the duct, openings must be placed every 12 feet of horizontal ductwork and every floor of vertical ductwork to ensure cleaning tools and high-pressure wands can reach every square inch. When these access points are missing, it doesn’t just make cleaning difficult; it makes the system non-compliant, often resulting in deficiencies on service reports that can complicate insurance claims or fire marshal inspections.

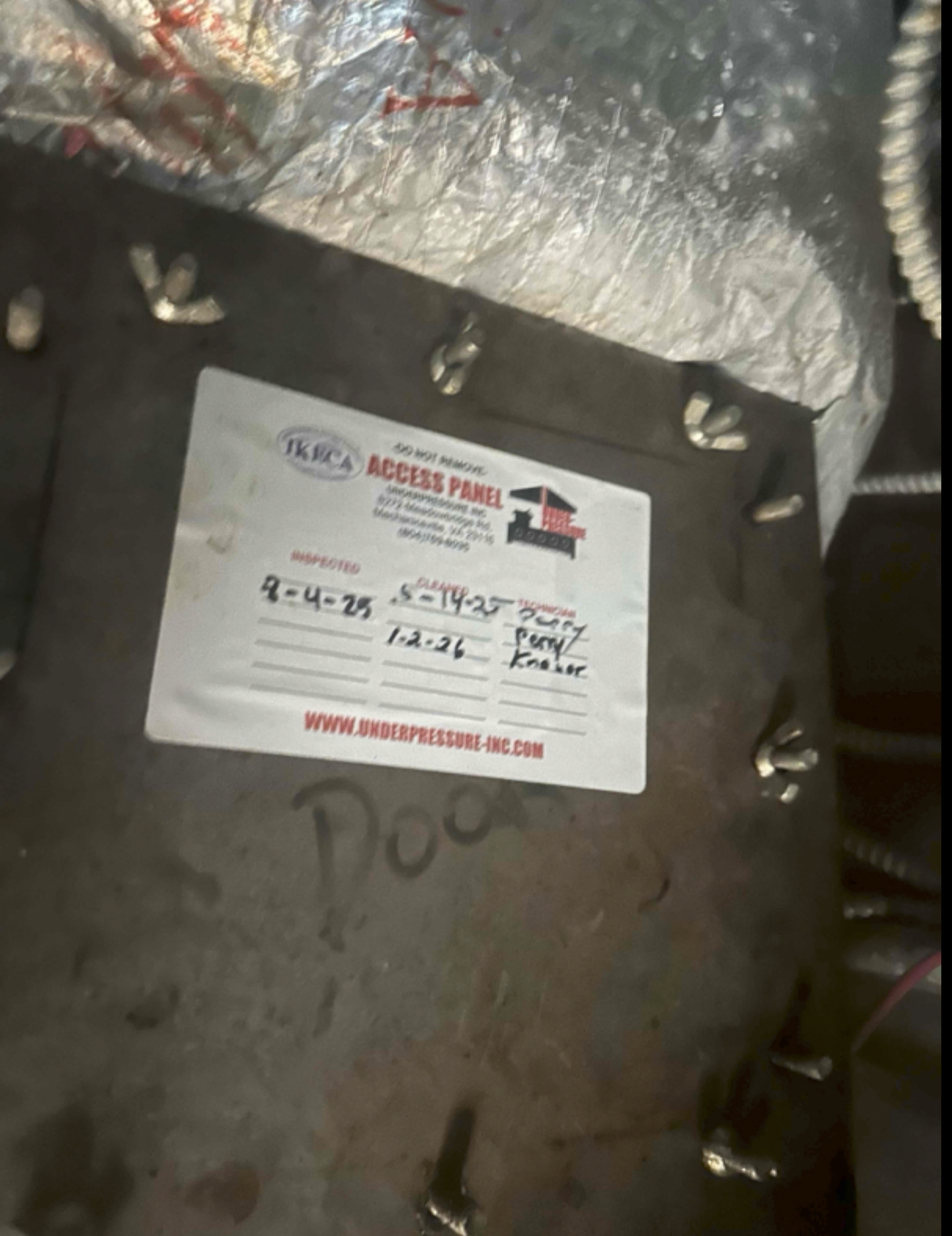

Fortunately, bringing a system into compliance is a routine and straightforward process. Installing a professional-grade access door does not require a massive construction project or significant kitchen downtime. In most cases, a technician can install a new, code-compliant door in a matter of minutes. The process involves a precise cutout and the installation of a UL-listed, bolt-on assembly that maintains the structural integrity of the duct without the need for complex welding. This minor, one-time update instantly transforms an "uncleanable" fire hazard into a maintainable, safe exhaust system.

Beyond mere placement, the construction of the access panels themselves is a vital component of the duct’s fire-rating. A compliant access door must be liquid-tight and constructed of the same heavy-gauge steel as the duct itself, utilizing specialized gaskets rated for 1500°F. Common mistakes, such as using fasteners that penetrate the duct wall or installing panels that are not easily reachable from a stable work platform, can compromise the system's safety. For owners, investing in the installation of proper, listed access doors is not just a maintenance cost—it is a critical fire-life safety upgrade that ensures your exhaust system functions as the engineered fire barrier it was designed to be.

Further Information: Duct Access Requirements